As a supplier of Automatic Carton Folding Machines, I often encounter inquiries from clients about the possibility of integrating our machines with other packaging equipment. This blog post aims to delve into this topic, exploring the feasibility, benefits, and considerations of such integration.

Feasibility of Integration

The short answer is yes, an Automatic Carton Folding Machine can be integrated with other packaging equipment. Thanks to advancements in technology, modern packaging machinery is designed with a high degree of flexibility and compatibility. Most Automatic Carton Folding Machines are equipped with standard interfaces and communication protocols that allow them to communicate and work in tandem with other equipment.

For example, our Automatic Carton Folding Machines can be easily integrated with labeling machines. After the cartons are folded, they can be directly transferred to the labeling machine for product information and branding. Similarly, they can be connected to filling machines. Once the cartons are ready, they can be filled with products, whether it's food, beverages, or consumer goods.

Benefits of Integration

1. Increased Efficiency

One of the primary benefits of integrating an Automatic Carton Folding Machine with other packaging equipment is increased efficiency. By eliminating the need for manual handling and transfer between different machines, the overall packaging process becomes faster. For instance, in a traditional packaging line, workers may need to move folded cartons from the folding machine to the filling machine. This not only takes time but also increases the risk of errors. With integration, the process is seamless, and the packaging speed can be significantly improved.

2. Cost Savings

Integration can also lead to cost savings. By streamlining the packaging process, companies can reduce labor costs. Fewer workers are needed to operate and transfer products between different machines. Additionally, integrated systems often have better energy efficiency, as they can be optimized to work together, reducing overall energy consumption.

3. Improved Quality Control

When an Automatic Carton Folding Machine is integrated with other packaging equipment, it becomes easier to implement quality control measures. For example, sensors can be installed at various points in the packaging line to detect any defects in the folded cartons or the filled products. If a defect is detected, the system can automatically reject the faulty item, ensuring that only high - quality products reach the market.

Considerations for Integration

1. Compatibility

Before integrating an Automatic Carton Folding Machine with other packaging equipment, it is crucial to ensure compatibility. This includes mechanical compatibility, such as the size and shape of the cartons and the transfer mechanisms between machines. It also involves electrical and communication compatibility. Make sure that the machines use the same communication protocols so that they can exchange data and operate in sync.

2. Space Requirements

Integrating multiple packaging machines requires adequate space. You need to consider the footprint of each machine and the space needed for the transfer conveyors and other connecting components. Proper layout planning is essential to ensure a smooth and efficient operation.

3. Maintenance and Support

With an integrated packaging system, maintenance becomes more complex. It is important to have a comprehensive maintenance plan in place. Ensure that the suppliers of all the machines, including the Automatic Carton Folding Machine, provide good technical support. This will help minimize downtime in case of any breakdowns.

Examples of Integration

Let's take a look at some real - world examples of how an Automatic Carton Folding Machine can be integrated with other packaging equipment.

1. Integration with a Labeling Machine

In a consumer goods packaging line, an Automatic Carton Folding Machine can be directly connected to a labeling machine. After the cartons are folded, they are transferred to the labeling machine via a conveyor belt. The labeling machine then applies product labels, barcodes, and other necessary information. This integration ensures that the labeling process is accurate and efficient, as the cartons are in a consistent position and orientation.

2. Integration with a Filling Machine

For food and beverage packaging, an Automatic Carton Folding Machine can be integrated with a filling machine. Once the cartons are folded, they are transported to the filling station. The filling machine then fills the cartons with the appropriate product, such as juice, milk, or cereal. This integration eliminates the need for manual handling of the cartons, reducing the risk of contamination and improving the overall packaging speed.

Our Products and Their Integration Capabilities

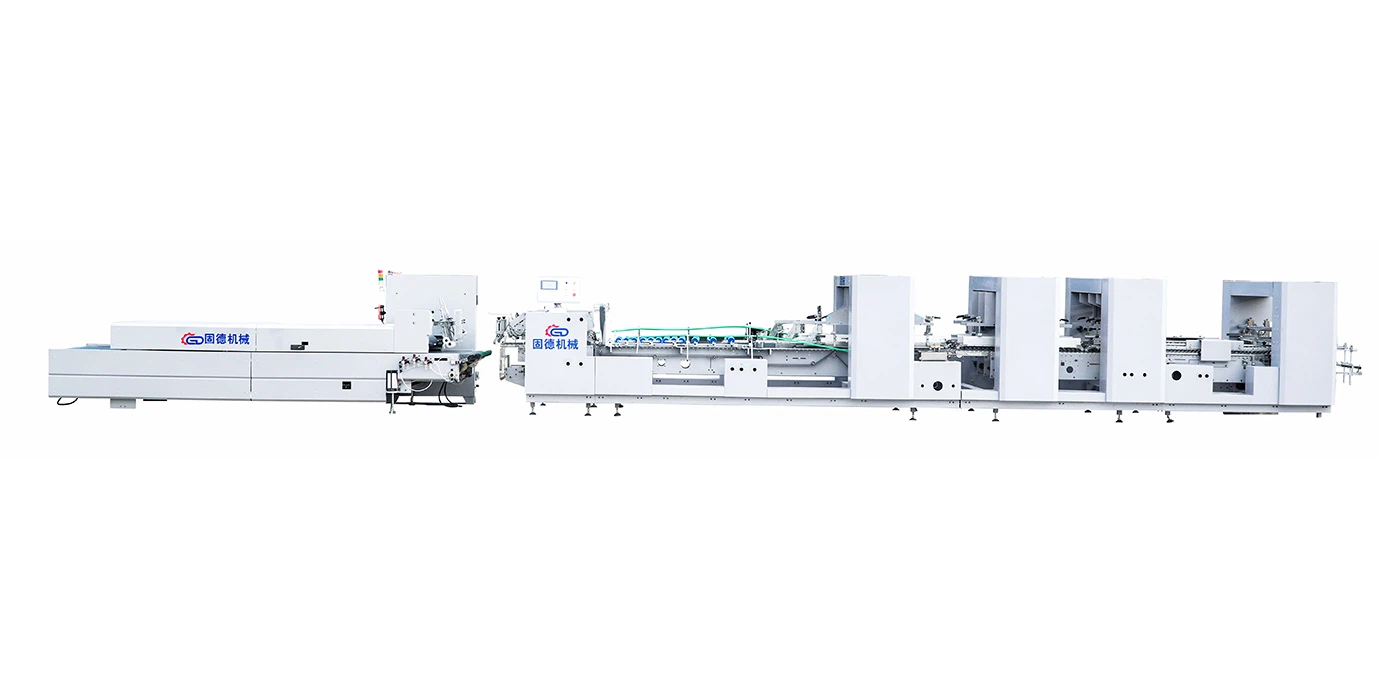

As a supplier of Automatic Carton Folding Machines, we offer a range of products that are designed with integration in mind. Our machines are equipped with state - of - the - art technology and standard interfaces, making them highly compatible with other packaging equipment.

For example, our Automatic Crash Lock Bottom Folder Gluer Parts are designed to work seamlessly with other components in a packaging line. These parts ensure that the cartons are folded accurately and efficiently, and can be easily integrated with labeling, filling, and sealing machines.

Our Carton Folder Gluer with Lock Bottom is another product that offers excellent integration capabilities. It can be connected to various types of packaging equipment, allowing for a complete and efficient packaging solution.

In addition, our Corrugated Box Folder Gluer Machine is suitable for integrating into large - scale packaging lines. It can handle corrugated boxes of different sizes and shapes, and can be easily connected to other equipment for a comprehensive packaging process.

Conclusion

In conclusion, integrating an Automatic Carton Folding Machine with other packaging equipment is not only feasible but also offers numerous benefits, including increased efficiency, cost savings, and improved quality control. However, it is important to consider factors such as compatibility, space requirements, and maintenance when planning an integrated packaging system.

As a supplier, we are committed to providing high - quality Automatic Carton Folding Machines that are easy to integrate with other packaging equipment. If you are interested in learning more about our products or exploring the possibility of integrating them into your packaging line, please feel free to contact us for a detailed consultation and procurement discussion.

References

- Packaging Machinery Manufacturers Institute (PMMI). "Trends in Packaging Machinery Integration."

- Industry reports on packaging technology and equipment integration.