Ensuring the stability of a lock bottom folder gluer during operation is crucial for any packaging production line. As a reliable lock bottom folder gluer supplier, I understand the significance of a stable machine in delivering high - quality packaging products efficiently. In this blog, I will share some key strategies and practices to maintain the stability of a lock bottom folder gluer during its operation.

1. Machine Installation and Setup

Proper installation is the first step towards ensuring the stability of a lock bottom folder gluer. Before installation, it is essential to choose a suitable location. The floor should be flat, level, and capable of supporting the weight of the machine. Uneven floors can cause the machine to vibrate during operation, leading to misalignments and poor performance.

During the installation process, strict adherence to the manufacturer's guidelines is necessary. All components should be correctly assembled and tightened. The conveyor belts, folding plates, and gluing units should be precisely aligned. Misaligned components can result in jams, inaccurate folding, and inconsistent glue application. For example, if the folding plates are not properly aligned, the cartons may not fold correctly, leading to production waste.

Once the machine is installed, a thorough calibration is required. This includes setting the correct pressure for the folding and gluing mechanisms, adjusting the speed of the conveyor belts, and ensuring the accurate positioning of the carton blanks. Calibration should be done regularly, especially after any major maintenance or when switching to a different carton size.

2. Regular Maintenance

Regular maintenance is the cornerstone of machine stability. A well - maintained lock bottom folder gluer is less likely to experience breakdowns and will operate more consistently.

- Cleaning: Regular cleaning of the machine is essential. Dust, debris, and dried glue can accumulate on the conveyor belts, folding plates, and glue applicators. This can affect the movement of the carton blanks and the quality of the glue application. Cleaning should be done daily or after each production run. Use appropriate cleaning agents and tools to avoid damaging the machine components. For instance, a soft brush can be used to clean the hard - to - reach areas, while a mild detergent can be used to clean the conveyor belts.

- Lubrication: Moving parts of the machine, such as bearings, gears, and chains, require proper lubrication. Lubrication reduces friction, wear, and tear, and helps to keep the machine running smoothly. The type and frequency of lubrication depend on the machine's specifications. Some parts may need to be lubricated daily, while others can be lubricated weekly or monthly. It is important to use the recommended lubricants to ensure optimal performance.

- Inspection: Regular inspections should be carried out to identify any potential issues before they become major problems. Check for loose bolts, worn - out parts, and signs of damage. Inspect the electrical components for any signs of overheating or short - circuits. Replace any damaged or worn - out parts immediately to prevent further damage to the machine.

3. Operator Training

Well - trained operators are essential for the stable operation of a lock bottom folder gluer. Operators should have a thorough understanding of the machine's functions, controls, and safety procedures.

- Initial Training: When new operators are hired, they should receive comprehensive training on the lock bottom folder gluer. This includes theoretical training on the machine's working principles, as well as practical training on how to operate the machine safely and efficiently. The training should cover topics such as loading carton blanks, adjusting the machine settings, and troubleshooting common problems.

- Ongoing Training: As technology advances and new features are added to the machine, operators should receive ongoing training. This helps them to stay updated with the latest operating procedures and to make the most of the machine's capabilities. For example, if the machine is upgraded with a new glue application system, operators need to be trained on how to use it effectively.

- Safety Training: Safety should always be a top priority. Operators should be trained on how to use personal protective equipment (PPE), such as gloves and safety glasses. They should also be aware of the safety interlocks and emergency stop buttons on the machine. Regular safety drills can help to reinforce the importance of safety procedures.

4. Quality of Raw Materials

The quality of the raw materials used in the production process can also affect the stability of the lock bottom folder gluer.

- Carton Blanks: The carton blanks should be of high quality. They should have the correct thickness, stiffness, and moisture content. Carton blanks that are too thick or too stiff may cause jams in the machine, while those with high moisture content may not fold or glue properly. It is important to source carton blanks from reliable suppliers and to store them in a dry environment.

- Glue: The glue used in the gluing process should be suitable for the type of carton material and the production requirements. Low - quality glue may not provide a strong bond, leading to cartons coming apart during handling. On the other hand, using the wrong type of glue can also cause problems, such as clogging the glue applicator. It is recommended to test different types of glue to find the one that works best for your specific application.

5. Monitoring and Control Systems

Modern lock bottom folder gluers are often equipped with monitoring and control systems that can help to ensure stability during operation.

- Sensor Technology: Sensors can be used to monitor various parameters of the machine, such as the position of the carton blanks, the speed of the conveyor belts, and the pressure of the folding and gluing mechanisms. If any of these parameters deviate from the set values, the sensor can trigger an alarm or automatically adjust the machine settings. For example, if the sensor detects that a carton blank is not properly positioned, it can stop the machine to prevent a jam.

- Data Analysis: The data collected by the monitoring systems can be analyzed to identify trends and potential problems. By analyzing the data, operators can make informed decisions about machine maintenance, adjustments, and production planning. For example, if the data shows that the machine is experiencing more jams during a certain shift, it may indicate a problem with the operator's technique or the quality of the raw materials.

6. Upgrades and Improvements

As the packaging industry evolves, it is important to keep the lock bottom folder gluer up - to - date. Upgrading the machine with the latest technology can improve its stability and performance.

- Software Updates: Many modern lock bottom folder gluers are controlled by software. Regular software updates can fix bugs, improve functionality, and add new features. For example, a software update may improve the accuracy of the glue application system or enhance the machine's ability to handle different carton sizes.

- Hardware Upgrades: Upgrading the hardware components of the machine, such as the conveyor belts, folding plates, or glue applicators, can also improve its stability. Newer components may be more durable, efficient, and accurate. For example, upgrading to a high - speed conveyor belt can increase the production capacity of the machine without sacrificing stability.

In conclusion, ensuring the stability of a lock bottom folder gluer during operation requires a comprehensive approach that includes proper installation, regular maintenance, operator training, quality raw materials, monitoring and control systems, and upgrades. By implementing these strategies, you can minimize downtime, improve product quality, and increase the overall efficiency of your packaging production line.

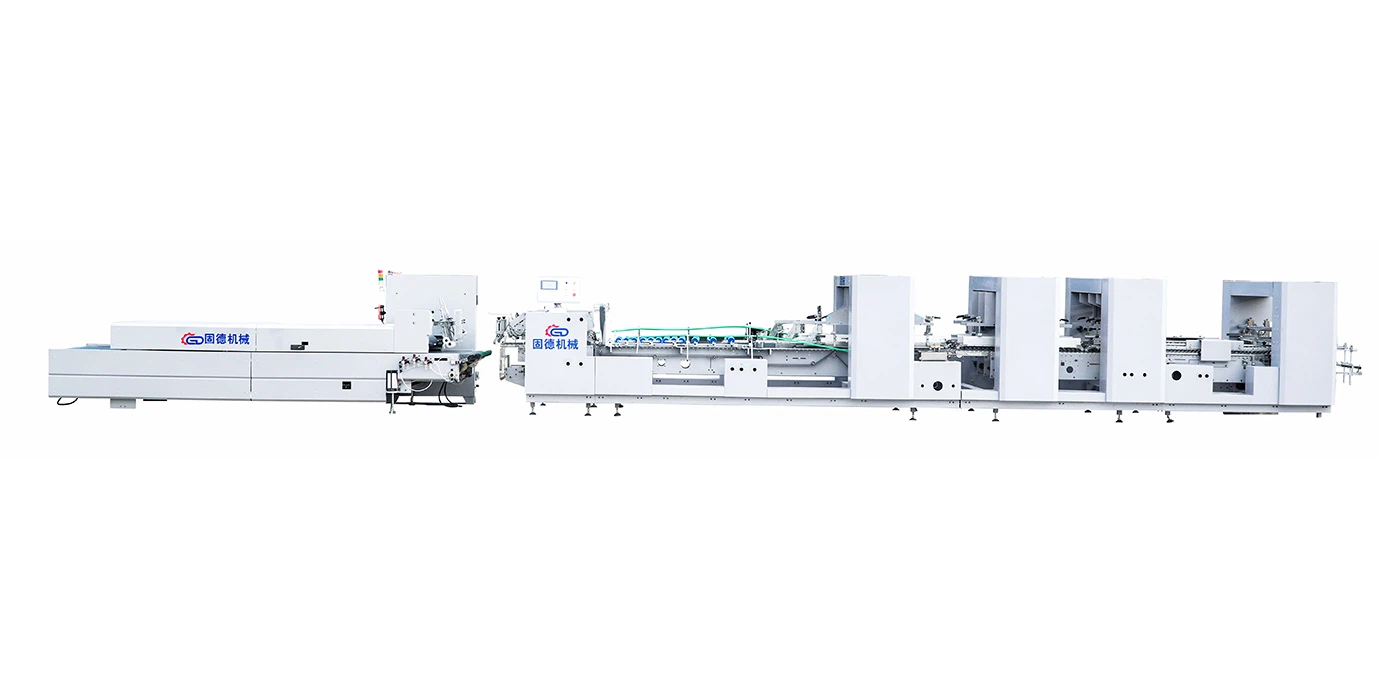

If you are interested in learning more about our Semi Automatic Folder Gluer Machine, Automatic Crash Lock Bottom Folder Gluer Parts, or Lock Bottom Folder Gluer High Speed, or if you have any questions about ensuring the stability of your lock bottom folder gluer, please feel free to contact us for a detailed discussion and potential purchase negotiation.

References

- Packaging Machinery Manufacturers Institute (PMMI). (2023). Best Practices for Maintaining Packaging Equipment.

- Smith, J. (2022). The Importance of Quality Control in Packaging Production. Journal of Packaging Science.

- Brown, A. (2021). Advancements in Lock Bottom Folder Gluer Technology. Packaging World Magazine.