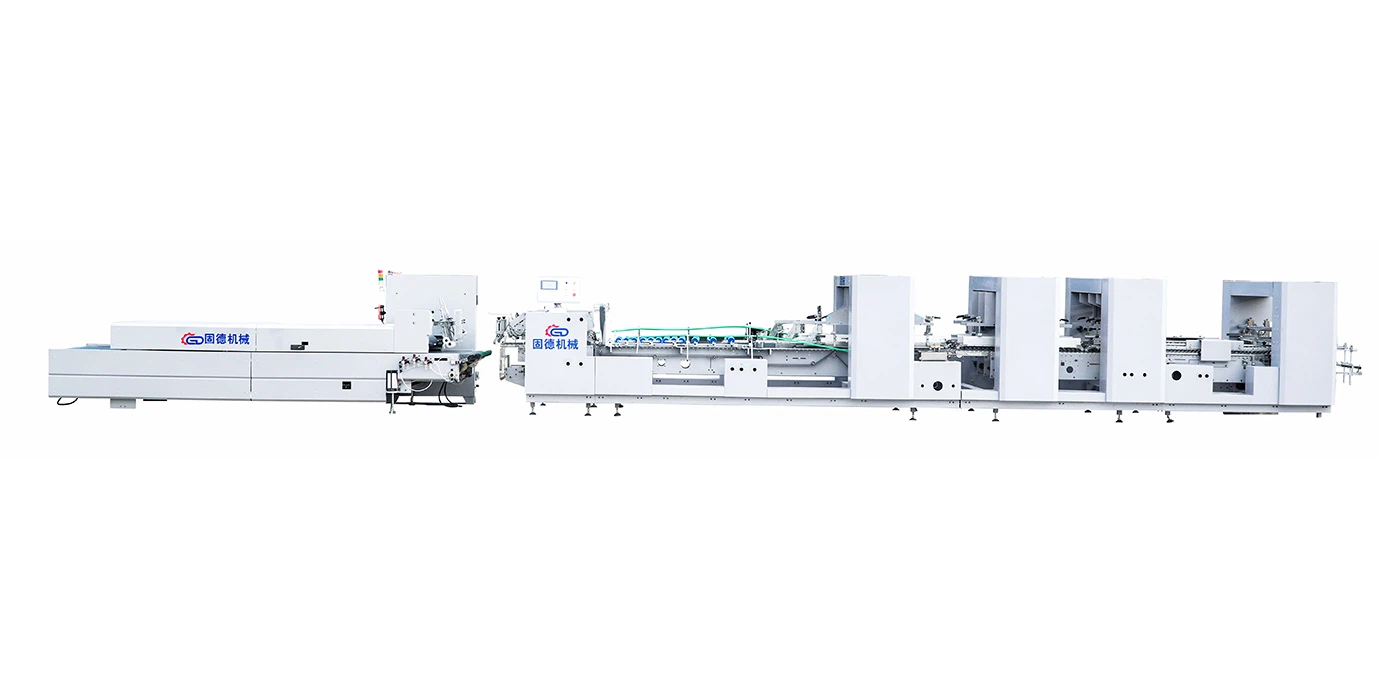

Hey there! As a supplier of Box Folding and Gluing Machines, I've seen firsthand how crucial folding precision is in the packaging industry. In this blog, I'm gonna share some tips on how to improve the folding precision of a Box Folding and Gluing Machine.

Understanding the Basics

First things first, let's understand what affects the folding precision. The folding precision of a Box Folding and Gluing Machine is influenced by several factors, including the machine's mechanical structure, the quality of the materials being folded, and the settings of the machine.

The mechanical structure of the machine plays a significant role. A well - built machine with high - quality components will generally offer better precision. For example, if the folding plates and guides are made of durable and precisely machined materials, they can ensure more accurate folding.

The quality of the materials being folded also matters. Different types of cardboard or paper have different properties such as thickness, stiffness, and moisture content. Thicker and stiffer materials might require more force to fold accurately, while materials with high moisture content can be more difficult to handle and may lead to uneven folds.

Machine Maintenance

One of the most important aspects of improving folding precision is regular machine maintenance. Just like a car, a Box Folding and Gluing Machine needs proper care to perform at its best.

- Cleaning: Regularly clean the machine to remove dust, debris, and glue residues. Dust can accumulate on the folding mechanisms and guides, which can affect the smooth movement of the materials and lead to inaccurate folds. Glue residues can harden and cause blockages or uneven pressure on the materials during folding.

- Lubrication: Keep all moving parts well - lubricated. This includes the gears, bearings, and conveyor belts. Proper lubrication reduces friction, which not only improves the folding precision but also extends the lifespan of the machine.

- Inspection and Replacement: Regularly inspect the machine for worn - out parts. Parts like folding blades, belts, and rollers can wear over time. If these parts are not replaced in a timely manner, they can cause inconsistent folds. For instance, a worn - out folding blade might not cut or crease the material cleanly, resulting in rough or inaccurate folds.

Material Preparation

As I mentioned earlier, the quality of the materials being folded has a big impact on the folding precision. Here are some ways to prepare the materials properly:

- Moisture Control: Ensure that the materials have the right moisture content. You can use a moisture meter to check the moisture level. If the materials are too dry, they can become brittle and may crack during folding. On the other hand, if they are too moist, they can be difficult to fold neatly. You can adjust the moisture content by storing the materials in a controlled environment or using a humidifier or de - humidifier if necessary.

- Cutting and Creasing: Make sure the materials are cut and creased accurately before they enter the folding machine. Precise cutting and creasing can make the folding process much smoother. Use high - quality cutting and creasing tools, and check the alignment of the cuts and creases regularly.

Machine Settings

Adjusting the machine settings correctly is also key to improving folding precision.

- Folding Speed: The folding speed should be set according to the type and thickness of the materials. If the speed is too high, the machine may not have enough time to fold the materials accurately, especially for thicker or stiffer materials. On the other hand, if the speed is too low, it can reduce the production efficiency. Experiment with different speeds to find the optimal one for each type of material.

- Pressure Settings: The pressure applied during folding is crucial. Too much pressure can cause the material to tear or deform, while too little pressure may result in loose or incomplete folds. Adjust the pressure settings based on the material properties. You can start with the manufacturer's recommended settings and then make small adjustments as needed.

- Alignment: Ensure that the materials are properly aligned before they enter the folding area. Misaligned materials can lead to uneven folds. Check the alignment of the conveyor belts and guides regularly to make sure they are in the correct position.

Upgrading Machine Parts

Sometimes, upgrading certain machine parts can significantly improve folding precision.

For example, if you're using an older machine, upgrading to more advanced folding plates or guides can make a big difference. These upgraded parts are often designed with better precision and can handle a wider range of materials more effectively. You can find some great options for Automatic Crash Lock Bottom Folder Gluer Parts.

If your production volume is relatively small and you're looking for a more budget - friendly option, a Manual Box Gluing Machine can be a good choice. It may not have the same high - speed production capabilities as an automatic machine, but it can still offer decent folding precision with proper operation.

For medium - scale production, a Semi Automatic Folder Gluer Machine can be a great upgrade. It combines some of the advantages of manual and automatic machines, offering better precision and efficiency compared to a manual machine.

Operator Training

Even the best machine won't perform well if the operator doesn't know how to use it properly. Proper operator training is essential for improving folding precision.

- Machine Operation: Train the operators on how to operate the machine correctly, including how to set the parameters, load the materials, and troubleshoot common problems. Make sure they understand the importance of following the correct procedures.

- Material Handling: Teach the operators how to handle different types of materials. They should know how to adjust the machine settings based on the material properties and how to detect any issues with the materials that could affect the folding precision.

Conclusion

Improving the folding precision of a Box Folding and Gluing Machine is a combination of machine maintenance, proper material preparation, correct machine settings, possible part upgrades, and operator training. By paying attention to these aspects, you can significantly enhance the quality of your folded boxes and increase your production efficiency.

If you're interested in learning more about our Box Folding and Gluing Machines or have any questions regarding improving folding precision, feel free to get in touch with us. We're always here to help you find the best solutions for your packaging needs.

References

- Packaging Machinery Handbook: A comprehensive guide to understanding the operation and maintenance of packaging machines.

- Industry research reports on the latest trends and technologies in box folding and gluing.