Hey there! As a supplier of Automatic Flute Laminator Machines, I've seen my fair share of issues when it comes to the laminating process. One of the most common problems that customers face is uneven laminating. It can be a real headache, but don't worry! In this blog post, I'll break down the reasons behind uneven laminating in an Automatic Flute Laminator Machine and give you some insights on how to fix them.

1. Improper Glue Application

Glue is the key to a successful lamination process. If the glue isn't applied evenly, you're going to end up with uneven laminating. There are a few reasons why glue application might be off:

-

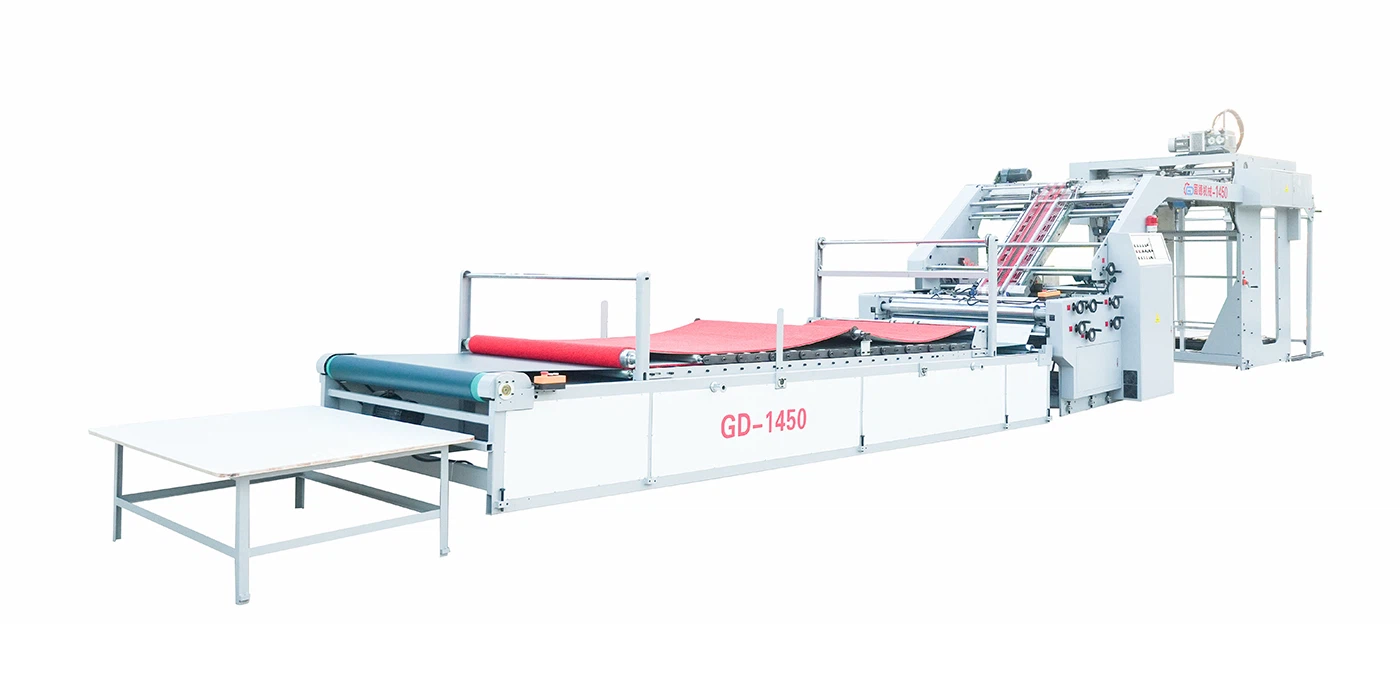

Glue Roller Issues: The glue roller is responsible for spreading the glue evenly on the material. If the roller is dirty, damaged, or worn out, it won't be able to distribute the glue properly. For example, if there's debris on the roller, it can create gaps in the glue layer, leading to uneven lamination. Regular cleaning and inspection of the glue roller are essential to ensure smooth and even glue application. You can check out our Automatic Flute Laminator which is designed with high - quality glue rollers for consistent performance.

-

Glue Viscosity: The viscosity of the glue matters a lot. If the glue is too thick, it won't spread easily, and you might get clumps or uneven patches. On the other hand, if it's too thin, it might not hold the layers together properly. You need to make sure the glue viscosity is within the recommended range for your specific machine and materials. Adjusting the temperature of the glue can sometimes help control its viscosity.

-

Glue Flow Rate: The flow rate of the glue from the reservoir to the roller also plays a role. If the flow rate is too high, there will be too much glue in some areas, causing blobs and unevenness. If it's too low, there won't be enough glue to bond the layers effectively. You can usually adjust the flow rate settings on your machine to find the sweet spot.

2. Material Issues

The materials you're using can also contribute to uneven laminating.

-

Uneven Material Thickness: If the corrugated board or the liner you're laminating has variations in thickness, it can lead to uneven pressure during the lamination process. For instance, a thicker area of the board might receive more pressure than a thinner area, resulting in inconsistent bonding. Before starting the lamination process, it's a good idea to check the thickness of your materials and sort out any pieces that are significantly different. Our Intelligent Automatic Flute Laminator has sensors that can detect some material thickness variations and adjust the pressure accordingly.

-

Material Surface Condition: The surface of the materials should be clean and free of dust, oil, or other contaminants. If there are impurities on the surface, the glue might not adhere properly, leading to uneven lamination. Make sure to store your materials in a clean environment and clean them if necessary before using them in the laminator.

-

Material Moisture Content: The moisture content of the materials can affect the lamination process. If the materials are too dry, the glue might dry too quickly and not bond well. If they're too wet, it can cause the glue to spread unevenly or even lead to warping of the materials. You should try to keep the moisture content of your materials within the recommended range.

3. Pressure and Temperature Problems

Pressure and temperature are two crucial factors in the lamination process.

-

Uneven Pressure Distribution: The pressure applied during lamination should be uniform across the entire surface of the materials. If the pressure is uneven, some areas will be more firmly bonded than others. This can be due to misaligned pressure rollers or a problem with the pressure adjustment mechanism. You need to regularly check and adjust the pressure settings on your machine to ensure even pressure distribution. Our Fully Automatic Corrugated Flute Laminator has advanced pressure control systems to help maintain consistent pressure.

-

Incorrect Temperature: Temperature affects the drying and bonding properties of the glue. If the temperature is too low, the glue might not dry properly, and the layers won't bond well. If it's too high, the glue can dry too quickly and become brittle, leading to poor adhesion. You need to set the temperature according to the type of glue and materials you're using. Make sure to monitor the temperature during the lamination process and make adjustments as needed.

4. Machine Alignment and Calibration

A misaligned or poorly calibrated machine can cause a whole host of problems, including uneven laminating.

-

Roller Alignment: The rollers in the laminator need to be properly aligned. If they're not, it can create uneven pressure and cause the materials to shift during the lamination process. Regularly check the alignment of the rollers and make any necessary adjustments. You might need to use alignment tools provided by the machine manufacturer.

-

Machine Calibration: The machine should be calibrated regularly to ensure accurate operation. This includes calibrating the speed, pressure, temperature, and glue application settings. A poorly calibrated machine can lead to inconsistent results. Follow the manufacturer's instructions for calibration and do it at regular intervals to keep your machine in top shape.

5. Operator Error

Sometimes, the root cause of uneven laminating can be operator error.

-

Improper Loading: Loading the materials into the machine incorrectly can cause problems. If the materials are not fed straight or are misaligned, it can lead to uneven lamination. Operators should be trained on the proper loading procedures to ensure smooth operation.

-

Incorrect Settings: Operators need to set the machine parameters correctly based on the materials and glue being used. Using the wrong settings for speed, pressure, or temperature can result in uneven laminating. Make sure your operators are well - trained and understand how to adjust the settings for different jobs.

So, there you have it! These are the main reasons for uneven laminating in an Automatic Flute Laminator Machine. By understanding these issues and taking the necessary steps to address them, you can improve the quality of your lamination process.

If you're having problems with uneven laminating or are looking to upgrade your current laminator, we're here to help. Our range of Automatic Flute Laminator, Intelligent Automatic Flute Laminator, and Fully Automatic Corrugated Flute Laminator are designed to provide reliable and high - quality lamination results. Contact us to discuss your specific needs and let's work together to find the perfect solution for your business.

References

- Packaging Machinery Handbook: This handbook provides in - depth information on the operation and maintenance of packaging machinery, including flute laminators.

- Industry research reports on corrugated packaging production: These reports offer insights into the latest trends and best practices in the corrugated packaging industry, which can be useful for understanding laminating issues.