Hey there! As a supplier of semi - automatic folder gluer machines, I've seen a lot of folks new to the game scratching their heads about the learning curve of operating these nifty devices. So, let's dive right in and break it down.

Getting Familiar with the Basics

First things first, when you get your hands on a semi - automatic folder gluer machine, it can look a bit intimidating. There are all these levers, buttons, and gizmos. But don't worry, it's not as complicated as it seems at first glance.

The semi - automatic folder gluer machine is mainly used for folding and gluing cartons. It's a great tool for small to medium - sized businesses that want to step up their packaging game without breaking the bank. The learning curve starts with understanding the machine's main components. You've got the feeder, which is responsible for feeding the carton blanks into the machine. Then there's the folding section, where the magic of shaping the cartons happens. And of course, the gluing unit, which applies the glue precisely where it's needed.

It usually takes a newbie operator a few days to get a hang of these basic components. You'll need to learn how to adjust the feeder to handle different sizes of carton blanks. For example, if you're working with smaller cartons, you'll need to make some tweaks to ensure a smooth feed. This might involve adjusting the guides and the speed of the feeder.

Learning the Controls

Once you're comfortable with the components, it's time to tackle the controls. Most semi - automatic folder gluer machines come with a control panel that looks like something out of a sci - fi movie. But in reality, it's not that hard to figure out.

The control panel allows you to set things like the folding speed, the amount of glue to be applied, and the position of the folds. You'll start by learning the basic functions. For instance, how to turn the machine on and off, how to start and stop the feeding process. These are the building blocks of operating the machine.

After getting the hang of the basics, you'll move on to more advanced settings. Let's say you want to change the folding pattern. You'll need to access the programming section of the control panel. This might seem a bit daunting at first, but with a bit of practice, you'll be programming different folding patterns like a pro. It typically takes about a week of consistent practice for an operator to become proficient in using the control panel.

Setting Up for Different Carton Types

One of the challenges in operating a semi - automatic folder gluer machine is setting it up for different types of cartons. There are various carton styles, such as straight tuck end cartons, lock bottom cartons, and crash lock bottom cartons. Each style requires a different setup.

For a straight tuck end carton, the setup is relatively straightforward. You'll need to adjust the folding blades and the glue application points according to the dimensions of the carton. However, when it comes to more complex cartons like lock bottom cartons, things get a bit more complicated.

The Carton Folder Gluer with Lock Bottom is designed to handle these more intricate carton styles. Setting up the machine for lock bottom cartons involves precise adjustments of the folding and gluing mechanisms. You'll need to ensure that the locks are formed correctly and that the glue is applied in the right places to hold the carton together. This part of the learning curve can take a couple of weeks to master, especially if you're dealing with different sizes and thicknesses of carton materials.

Quality Control and Troubleshooting

Once you're up and running with the machine, quality control becomes a crucial part of the process. You'll need to check each carton as it comes out of the machine to ensure that it meets the required standards. This involves looking for things like proper folding, accurate glue application, and no signs of damage.

If you notice any issues, you'll need to troubleshoot the machine. For example, if the cartons are not folding correctly, it could be due to a misaligned folding blade or an issue with the feeding mechanism. Troubleshooting skills take time to develop. You'll learn to identify common problems and how to fix them through trial and error.

As an operator gains more experience, they'll be able to spot potential issues before they become major problems. This is an important skill that can save a lot of time and money in the long run. It usually takes a few months of hands - on experience to become really good at quality control and troubleshooting.

Advanced Features and Productivity

After mastering the basics, you can start exploring the advanced features of the semi - automatic folder gluer machine. Some machines come with features like automatic glue level detection, which ensures that you never run out of glue during a production run. Others have advanced folding algorithms that can create more complex carton designs.

Learning to use these advanced features can significantly boost productivity. For example, if you're using the Automatic Crash Lock Bottom Folder Gluer Parts, you can take advantage of its high - speed folding and gluing capabilities. By learning to optimize these features, you can produce more cartons in less time.

However, these advanced features also come with a steeper learning curve. It might take another few months to fully understand and utilize all the advanced functions of the machine. But once you do, you'll see a significant improvement in your production efficiency.

The Overall Learning Curve

So, what's the overall learning curve for operating a semi - automatic folder gluer machine? Well, it varies from person to person, but on average, it takes about 3 - 6 months for an operator to become fully proficient.

In the first week, you'll focus on getting familiar with the machine's components and basic controls. Over the next few weeks, you'll learn how to set up the machine for different carton types. Quality control and troubleshooting skills will develop over the first few months of operation. And finally, exploring and mastering the advanced features can take an additional few months.

Conclusion and Call to Action

If you're thinking about getting into the carton production business or looking to upgrade your existing machinery, a semi - automatic folder gluer machine is a great investment. And don't be put off by the learning curve. With a bit of patience and practice, you'll be operating the machine like a pro in no time.

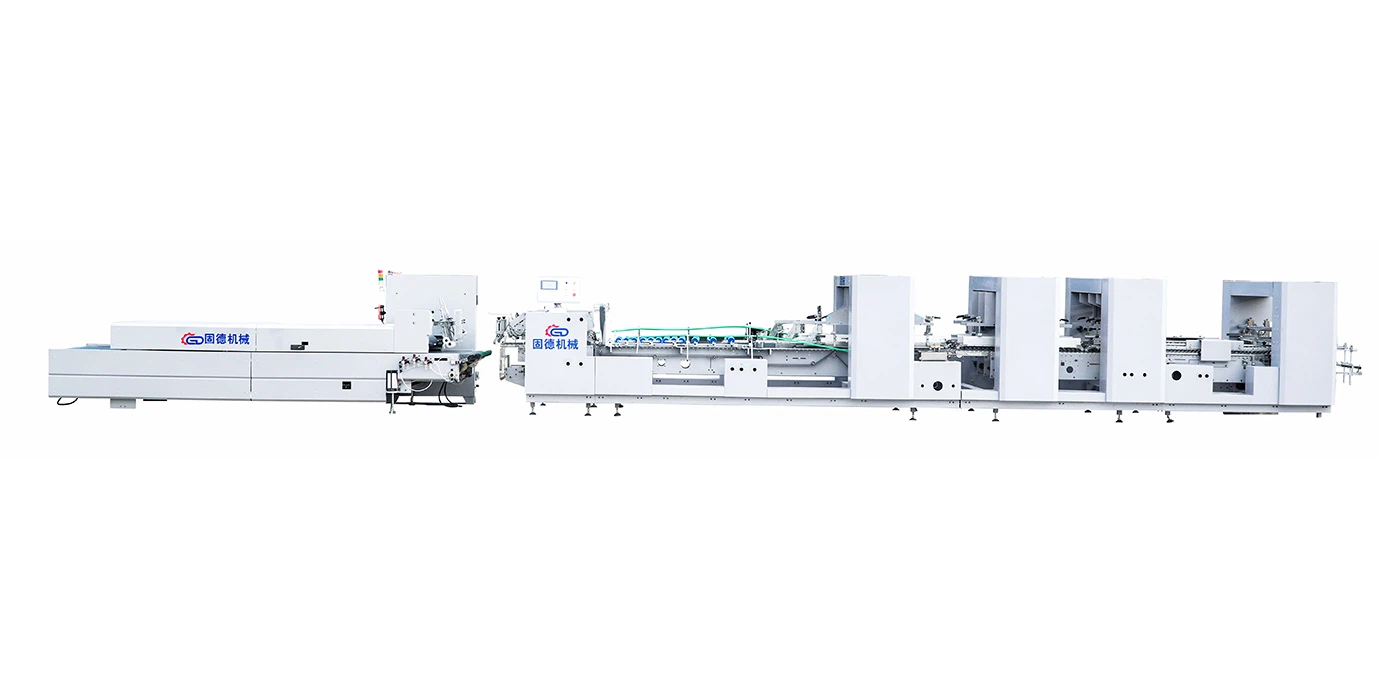

We offer a wide range of semi - automatic folder gluer machines, including the Automatic Carton Folder Gluer Machine. If you're interested in learning more about our products or have any questions about the learning curve or operation of these machines, we'd love to hear from you. Reach out to us, and let's start a conversation about how we can help you take your carton production to the next level.

References

- Industry knowledge and experience from years of supplying semi - automatic folder gluer machines.

- Training materials and manuals provided with the semi - automatic folder gluer machines.