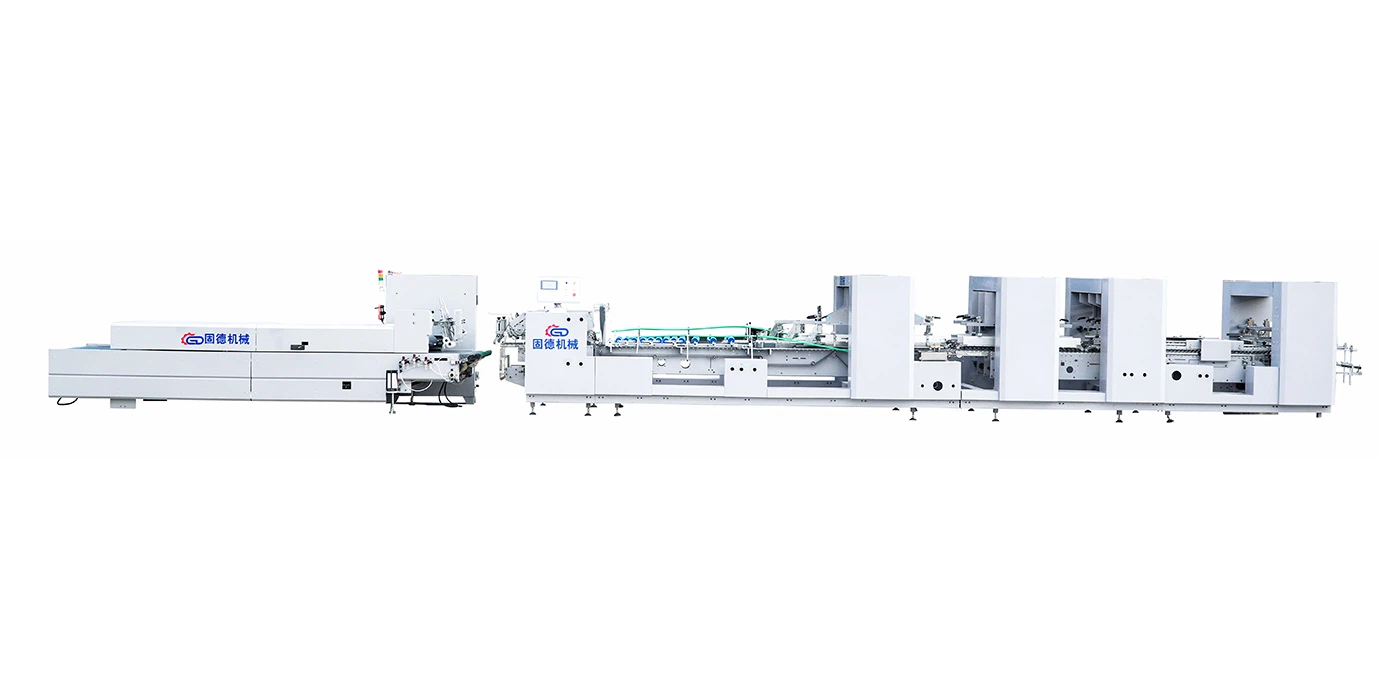

As a supplier of Lock Bottom Folder Gluer High Speed machines, I'm often asked about the intricacies of their lubrication systems. The lubrication system in these high - speed machines plays a pivotal role in ensuring smooth operation, longevity, and high - quality output. In this blog, I'll delve deep into what the lubrication system of the Lock Bottom Folder Gluer High Speed entails.

The Importance of Lubrication in Lock Bottom Folder Gluer High Speed

The Lock Bottom Folder Gluer High Speed is designed to operate at extremely high speeds, folding and gluing cartons with precision. With multiple moving parts such as gears, chains, and bearings, friction is inevitable. Friction not only causes wear and tear on these components but also generates heat. Excessive heat can lead to thermal expansion, which can throw off the machine's alignment and precision.

A well - functioning lubrication system reduces friction between moving parts. By creating a thin film of lubricant between surfaces, it minimizes direct contact, thus reducing wear and tear. This, in turn, extends the lifespan of the machine's components, reducing the frequency of part replacements and maintenance costs. Moreover, proper lubrication helps in dissipating heat, keeping the machine at an optimal operating temperature.

Components of the Lubrication System

Lubricant Reservoir

The lubricant reservoir is the heart of the lubrication system. It stores the lubricant, which is typically a specialized oil formulated to withstand the high - speed and high - stress conditions of the Lock Bottom Folder Gluer High Speed. The size of the reservoir is carefully designed to hold an adequate amount of lubricant to ensure continuous operation for an extended period without the need for frequent refilling.

Pumps

Pumps are responsible for circulating the lubricant throughout the system. In a Lock Bottom Folder Gluer High Speed, there are usually one or more pumps. These pumps are designed to deliver the lubricant at a consistent pressure to all the critical components. Some pumps are gear - driven, while others may be electrically powered, depending on the machine's design.

Filters

Filters are essential components of the lubrication system. They remove contaminants such as dirt, metal particles, and debris from the lubricant. Over time, these contaminants can accumulate in the lubricant and cause damage to the machine's components. By filtering the lubricant, the filters ensure that only clean lubricant reaches the moving parts, further protecting them from wear and tear.

Lubrication Points

Lubrication points are the specific locations on the machine where the lubricant is applied. These include gears, bearings, chains, and other moving parts. Each lubrication point has a specific requirement in terms of the amount and type of lubricant. The lubrication system is designed to deliver the right amount of lubricant to each point at the appropriate intervals.

Types of Lubrication

Splash Lubrication

Splash lubrication is a simple and cost - effective method used in some Lock Bottom Folder Gluer High Speed machines. In this method, the moving parts dip into a reservoir of lubricant, and as they move, they splash the lubricant onto other components. This method is suitable for low - to medium - speed applications where the components do not require a high - pressure supply of lubricant.

Pressure Lubrication

Pressure lubrication is the most common method used in high - speed Lock Bottom Folder Gluer machines. In this system, a pump is used to deliver the lubricant under pressure to the critical components. This ensures that all moving parts receive an adequate supply of lubricant, even at high speeds. Pressure lubrication is more efficient than splash lubrication and is better suited for machines that operate under heavy loads and high stress.

Mist Lubrication

Mist lubrication is a specialized method that involves creating a fine mist of lubricant and delivering it to the components. This method is particularly useful for hard - to - reach areas and components that require a light coating of lubricant. Mist lubrication can also help in reducing lubricant consumption, as only a small amount of lubricant is needed to create the mist.

Maintenance of the Lubrication System

Regular maintenance of the lubrication system is crucial for the proper functioning of the Lock Bottom Folder Gluer High Speed. Here are some key maintenance tasks:

- Lubricant Level Checks: Regularly check the lubricant level in the reservoir. If the level is low, refill it with the recommended lubricant.

- Filter Replacements: Replace the filters at the recommended intervals. A clogged filter can restrict the flow of lubricant and cause damage to the machine.

- Lubricant Analysis: Periodically analyze the lubricant to check for contaminants, wear particles, and changes in its properties. This can help in detecting potential problems early and taking corrective actions.

- Inspection of Lubrication Points: Inspect the lubrication points for any signs of leakage, blockage, or improper lubrication. Clean the lubrication points if necessary and ensure that they are functioning properly.

Impact of Lubrication on Machine Performance

A well - maintained lubrication system has a significant impact on the performance of the Lock Bottom Folder Gluer High Speed. Here's how:

- Improved Efficiency: Proper lubrication reduces friction, allowing the machine to operate more smoothly and efficiently. This results in higher production speeds and lower energy consumption.

- Enhanced Product Quality: By ensuring that the machine's components are operating smoothly, lubrication helps in maintaining the precision and accuracy of the folding and gluing process. This leads to higher - quality cartons with fewer defects.

- Reduced Downtime: A reliable lubrication system reduces the likelihood of component failures, which in turn reduces machine downtime. This means more production time and higher profitability for the user.

Related Products

If you're interested in other related products, we also offer Automatic Crash Lock Bottom Folder Gluer Parts, Semi Automatic Folder Gluer Machine, and Automatic Carton Folding Machine. These products complement our Lock Bottom Folder Gluer High Speed machines and can help you meet your specific packaging needs.

Conclusion

The lubrication system of the Lock Bottom Folder Gluer High Speed is a complex and critical part of the machine. It ensures smooth operation, reduces wear and tear, and enhances the overall performance and longevity of the machine. As a supplier, we understand the importance of a well - functioning lubrication system, and we are committed to providing high - quality machines with reliable lubrication systems.

If you're in the market for a Lock Bottom Folder Gluer High Speed machine or have any questions about our products, we encourage you to contact us for a procurement discussion. Our team of experts is ready to assist you in finding the right solution for your packaging requirements.

References

- Packaging Machinery Handbook, Third Edition

- Lubrication Engineering: Principles and Practice