Hey there! As a supplier of Corrugated Box Folder Gluer Machines, I often get asked about all sorts of technical aspects of these machines. One question that pops up quite a bit is, "What is the response time of the control system in a corrugated box folder gluer machine?" Well, let's dig into this topic and break it down.

First off, let's understand what we mean by the response time of the control system. In simple terms, it's the time it takes for the control system to detect a change in a parameter (like speed, position, or pressure) and then take appropriate action to correct or adjust it. For a corrugated box folder gluer machine, this is crucial because it directly affects the quality and efficiency of the box - making process.

In a corrugated box folder gluer machine, there are multiple components that rely on the control system. The feeding mechanism needs to be precisely timed to ensure that the corrugated sheets are fed at the right speed and position. The folding and gluing units also need to work in harmony, and any delay in the control system's response can lead to misaligned folds, improper gluing, or even jams in the machine.

Now, the response time of the control system can be influenced by several factors. One of the main factors is the type of sensors used in the machine. High - quality sensors can detect changes more quickly and accurately. For example, optical sensors can detect the presence or absence of a corrugated sheet in a fraction of a second. These sensors send signals to the control system, which then decides what action to take. Cheaper sensors might have a slower response time, leading to less precise control and potentially more errors in the box - making process.

Another factor is the processing power of the control system itself. Modern control systems use advanced microcontrollers and processors. A more powerful processor can analyze the sensor data faster and send out control signals more quickly. If the control system has a low - end processor, it might take longer to process the information, resulting in a longer response time.

The complexity of the control algorithm also plays a role. Some corrugated box folder gluer machines have simple control algorithms that only deal with basic functions like speed control. Others have more complex algorithms that can handle multiple variables simultaneously, such as adjusting the folding angle based on the thickness of the corrugated sheet. Naturally, more complex algorithms take longer to execute, which can increase the response time. However, they also offer more precise control and better overall performance.

Let's talk about the impact of response time on the machine's performance. A short response time means that the machine can adapt to changes in the production environment quickly. For instance, if there is a sudden change in the speed of the incoming corrugated sheets, a control system with a short response time can adjust the feeding and folding mechanisms immediately. This results in a smoother production process and higher - quality boxes.

On the other hand, a long response time can lead to a lot of problems. If the control system takes too long to respond to a change in the thickness of the corrugated sheet, the folding and gluing might not be done correctly. This can lead to boxes that are not properly sealed or have uneven folds. In a high - speed production environment, a long response time can cause a significant decrease in productivity as the machine might need to be stopped and restarted to correct the errors.

As a supplier, we always strive to provide machines with the shortest possible response time. We use high - end sensors and powerful processors in our machines. Our engineers are constantly working on optimizing the control algorithms to ensure that the machines can respond to changes as quickly as possible.

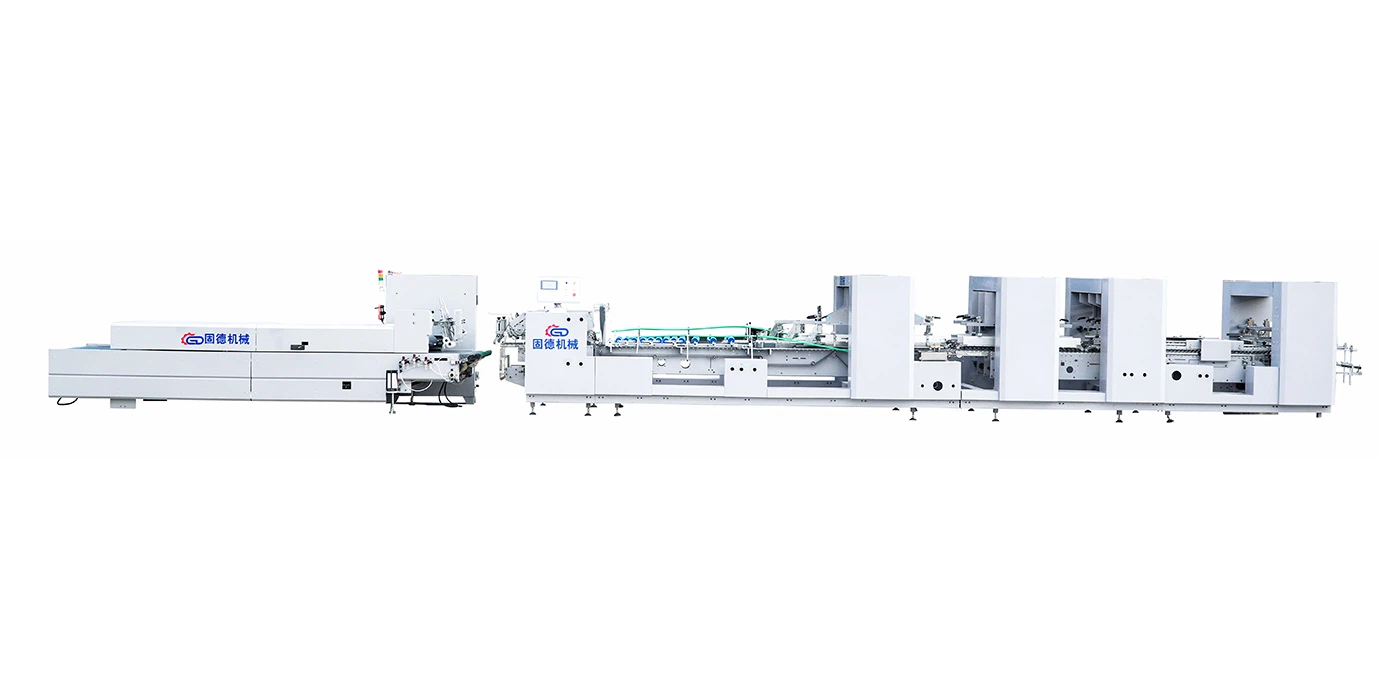

If you're in the market for a corrugated box folder gluer machine, you might be interested in some of our products. We have an Automatic Carton Folding Machine that offers excellent performance and a very short response time. This machine is designed to handle a wide range of corrugated sheet sizes and thicknesses, and its control system can adapt to different production requirements quickly.

We also have Automatic Crash Lock Bottom Folder Gluer Parts that are known for their reliability and precision. These parts are designed to work seamlessly with our control system, ensuring that the folding and gluing process is smooth and error - free.

For those who need a high - speed solution, our High Speed Crash Lock Bottom Pocket Folder Gluer is a great option. It can produce a large number of high - quality boxes in a short time, thanks to its fast - responding control system.

If you're looking to improve your box - making process and want a machine with a fast - responding control system, don't hesitate to reach out. We can provide you with detailed information about our products, and our team of experts can help you choose the right machine for your specific needs. Whether you're a small - scale producer or a large - scale factory, we have solutions that can fit your requirements.

In conclusion, the response time of the control system in a corrugated box folder gluer machine is a critical factor that affects the quality and efficiency of the box - making process. By understanding the factors that influence the response time and choosing a machine with a short response time, you can improve your productivity and the quality of your products. So, if you're ready to take your box - making business to the next level, get in touch with us today!

References:

- Industry reports on corrugated box manufacturing technology

- Technical specifications of sensors and processors used in industrial control systems

- Research papers on control algorithms for automated manufacturing machines