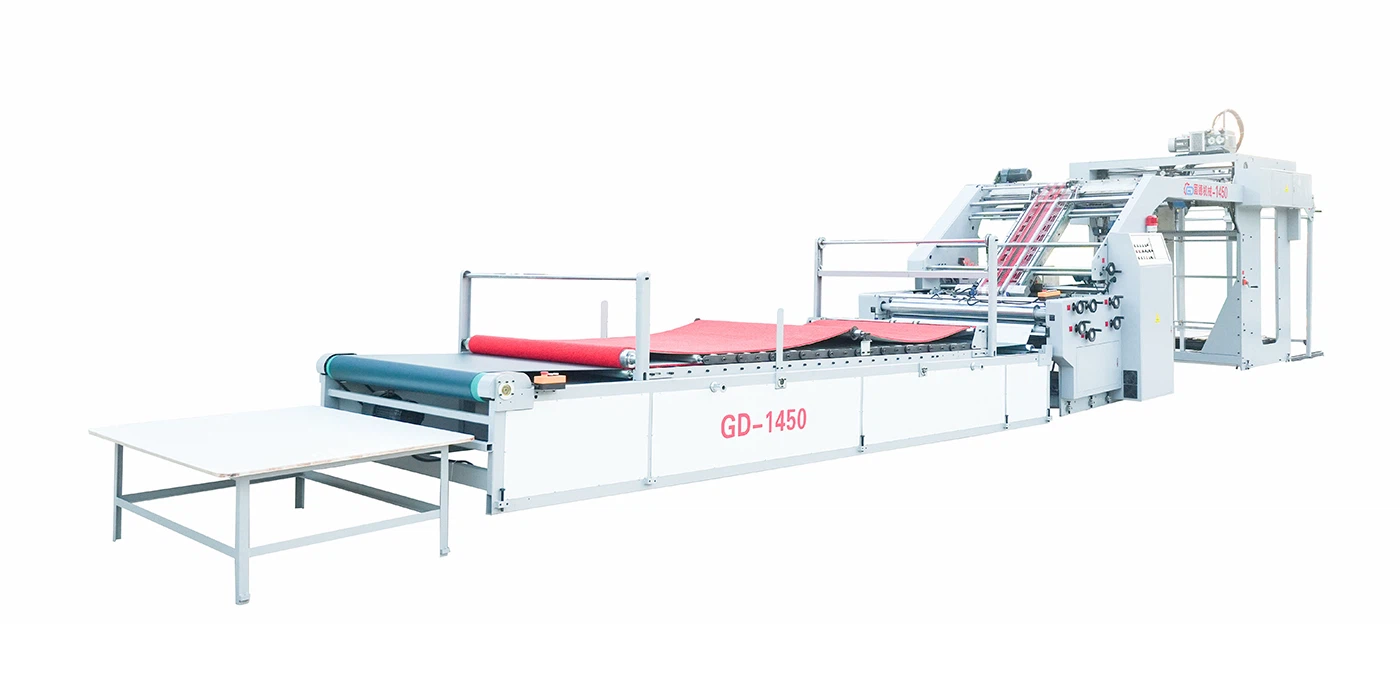

As a reputable supplier of 5 Ply Flute Laminators, I understand the significance of proper maintenance in ensuring the optimal performance and longevity of these machines. In this blog post, I'll delve into the essential maintenance requirements for a 5 Ply Flute Laminator, providing valuable insights to keep your equipment running smoothly.

Regular Cleaning

One of the fundamental maintenance tasks for a 5 Ply Flute Laminator is regular cleaning. Over time, dust, debris, and adhesive residues can accumulate on various components of the machine, which may affect its operation. It's crucial to clean the laminating rollers, conveyors, and other contact surfaces frequently. Use a soft, lint - free cloth and a mild cleaning solution recommended by the manufacturer.

For the laminating rollers, pay special attention to removing any dried adhesive. Adhesive build - up can cause uneven laminating pressure and result in poor lamination quality. You can use a scraper or a brush designed for this purpose to gently remove the stubborn residues. Make sure to follow the safety guidelines while performing this task to avoid any damage to the rollers.

The conveyor belts also need to be cleaned regularly. Remove any paper scraps or dust that may have settled on the belts. A dirty conveyor belt can cause slippage, which can disrupt the feeding process of the materials. Check the tension of the conveyor belts as well. If the belts are too loose or too tight, it can lead to misalignment of the materials during lamination.

Lubrication

Proper lubrication is vital for the smooth operation of a 5 Ply Flute Laminator. The moving parts of the machine, such as gears, bearings, and chains, need to be lubricated at regular intervals. Refer to the machine's manual for the recommended lubricants and the lubrication schedule.

For gears, use a high - quality gear lubricant that can withstand the high - pressure and high - speed operation of the laminator. Apply the lubricant evenly to ensure smooth meshing of the gears. Bearings, on the other hand, require a lubricant that can reduce friction and prevent overheating. Grease is often used for bearing lubrication. Make sure not to over - lubricate the bearings, as excess grease can attract dust and debris, which may cause premature wear.

Chains should be lubricated with a chain lubricant. This helps to reduce noise, prevent rusting, and ensure smooth movement of the chain. When lubricating the chains, run the machine at a slow speed to allow the lubricant to penetrate evenly into the chain links.

Inspection of Electrical Components

The electrical components of a 5 Ply Flute Laminator are critical for its proper functioning. Regularly inspect the wiring, connectors, and electrical panels. Look for any signs of frayed wires, loose connections, or overheating. Frayed wires can pose a serious safety hazard, such as electrical shock or fire. If you notice any damaged wires, replace them immediately with the appropriate ones.

Check the electrical connectors to ensure they are securely plugged in. Loose connectors can cause intermittent power supply, which can lead to machine malfunctions. Inspect the electrical panels for any signs of moisture or corrosion. Moisture can damage the electrical components and cause short - circuits. If you find any moisture in the panels, dry them thoroughly and take steps to prevent further moisture ingress.

The control system of the laminator, including the sensors and switches, also needs to be inspected. Make sure the sensors are clean and functioning properly. Dirty or malfunctioning sensors can cause incorrect readings, which can affect the lamination process. Test the switches to ensure they are operating smoothly and providing accurate signals.

Alignment and Calibration

Maintaining the proper alignment and calibration of a 5 Ply Flute Laminator is essential for achieving high - quality lamination results. Check the alignment of the laminating rollers regularly. Misaligned rollers can cause uneven pressure on the materials, resulting in wrinkling or poor adhesion. Use alignment tools provided by the manufacturer to ensure that the rollers are parallel and in the correct position.

Calibrate the temperature and pressure settings of the laminator according to the specifications of the materials being laminated. Different materials may require different temperature and pressure conditions for optimal lamination. Incorrect settings can lead to issues such as delamination or scorching of the materials. Refer to the machine's manual or consult with the manufacturer for the recommended calibration procedures.

Replacement of Wear Parts

Certain parts of a 5 Ply Flute Laminator are subject to wear and tear over time. These wear parts need to be replaced at the appropriate intervals to maintain the machine's performance. Some common wear parts include cutting blades, sealing strips, and filters.

Cutting blades can become dull after extended use. A dull blade can cause uneven cuts and may damage the materials. Replace the cutting blades when they start to show signs of wear, such as a rough or jagged edge. Sealing strips are used to prevent the leakage of adhesive and air. Over time, these strips can become worn or damaged. Replace them to ensure a tight seal and efficient lamination.

Filters, such as air filters and adhesive filters, need to be replaced regularly. A clogged filter can restrict the flow of air or adhesive, which can affect the machine's operation. Check the filters frequently and replace them according to the manufacturer's recommendations.

Training and Operator Awareness

Proper training of the operators is an important aspect of maintaining a 5 Ply Flute Laminator. Operators should be familiar with the machine's operation, maintenance procedures, and safety guidelines. Provide regular training sessions to keep the operators updated on the latest maintenance techniques and best practices.

Operators should also be aware of the signs of potential problems. For example, unusual noises, vibrations, or changes in the lamination quality can indicate a problem with the machine. Encourage the operators to report any such issues immediately so that they can be addressed promptly.

In conclusion, maintaining a 5 Ply Flute Laminator requires a comprehensive approach that includes regular cleaning, lubrication, inspection of electrical components, alignment and calibration, replacement of wear parts, and proper operator training. By following these maintenance requirements, you can ensure the reliable operation of your laminator and produce high - quality laminated products.

If you are in the market for a 5 Ply Flute Laminator or need more information about maintenance and operation, we are here to assist you. We offer a range of high - quality laminators, including the Intelligent Automatic Flute Laminator, Automatic Flute Laminator Machine, and Intelligent Flute Laminator Machine. Contact us to discuss your specific requirements and start a fruitful business partnership.

References

- Manufacturer's manual of the 5 Ply Flute Laminator

- Industry standards for laminating machine maintenance